|

This device was designed by Battelle Laboratories

for the US Army. Although the design is proprietary, it's not classified.

The original detailed solid model was created with SolidWorks. DeepSoft, LLC. created a substantially simplified model of just the structurally

significant components also in SolidWorks. This model was then transferred to

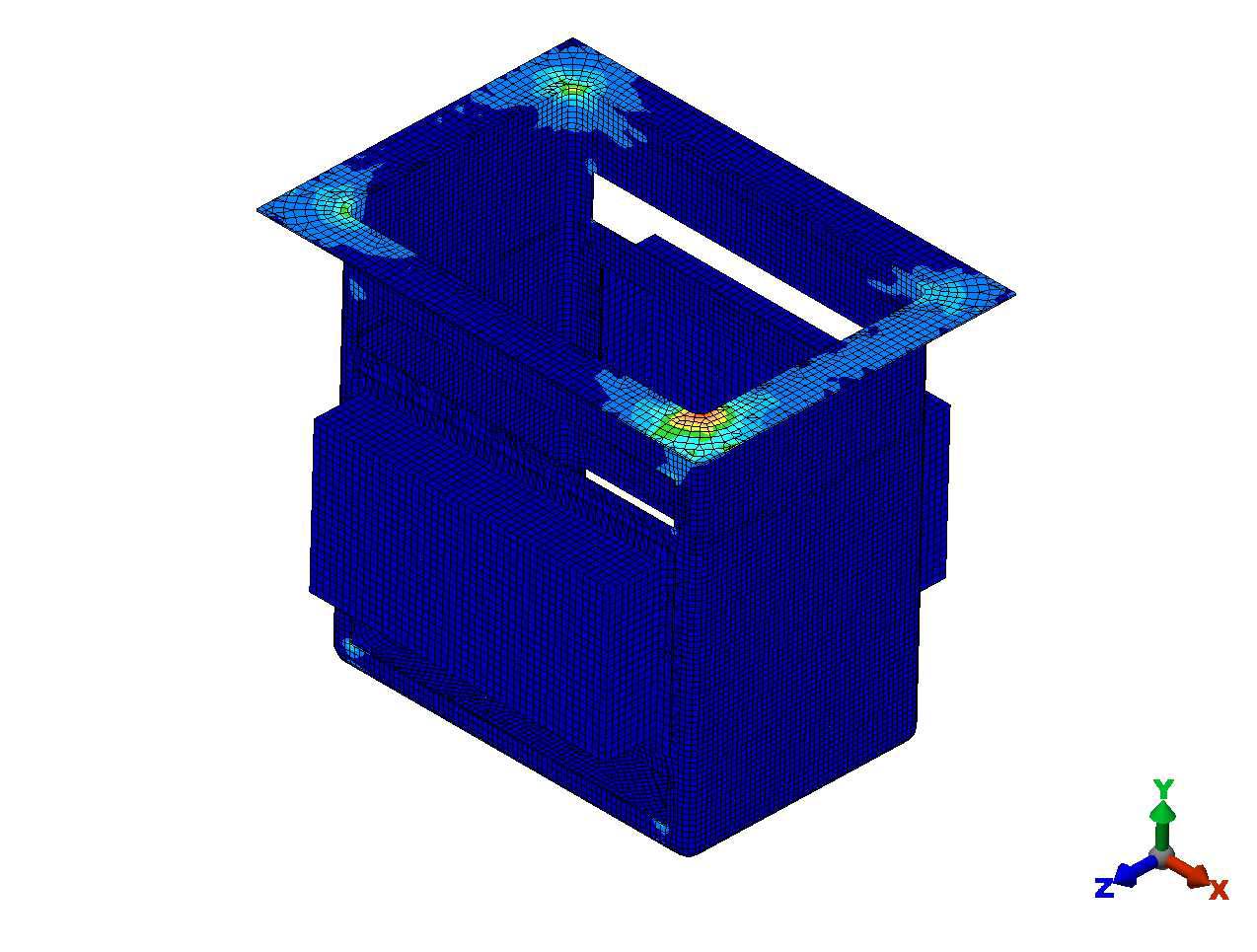

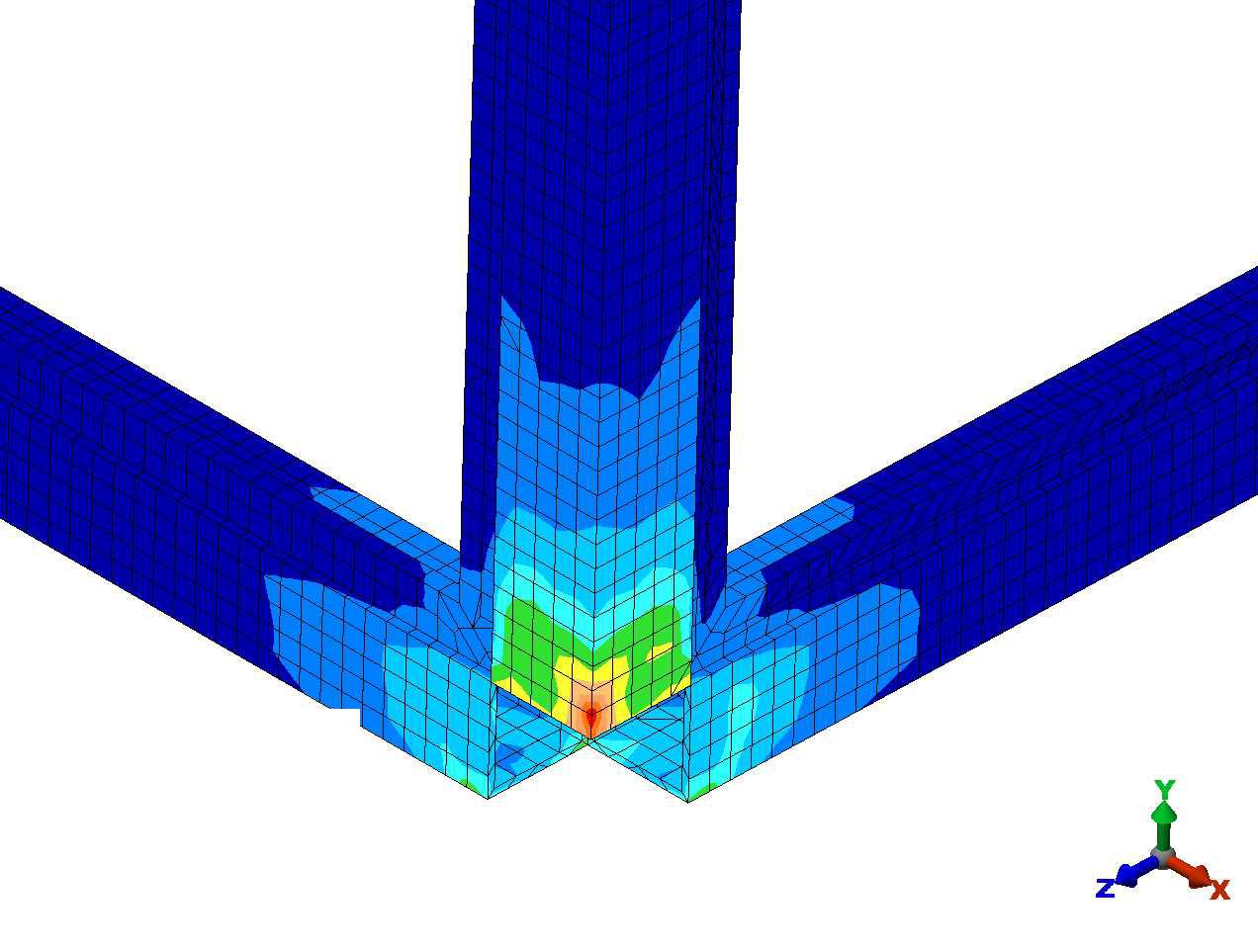

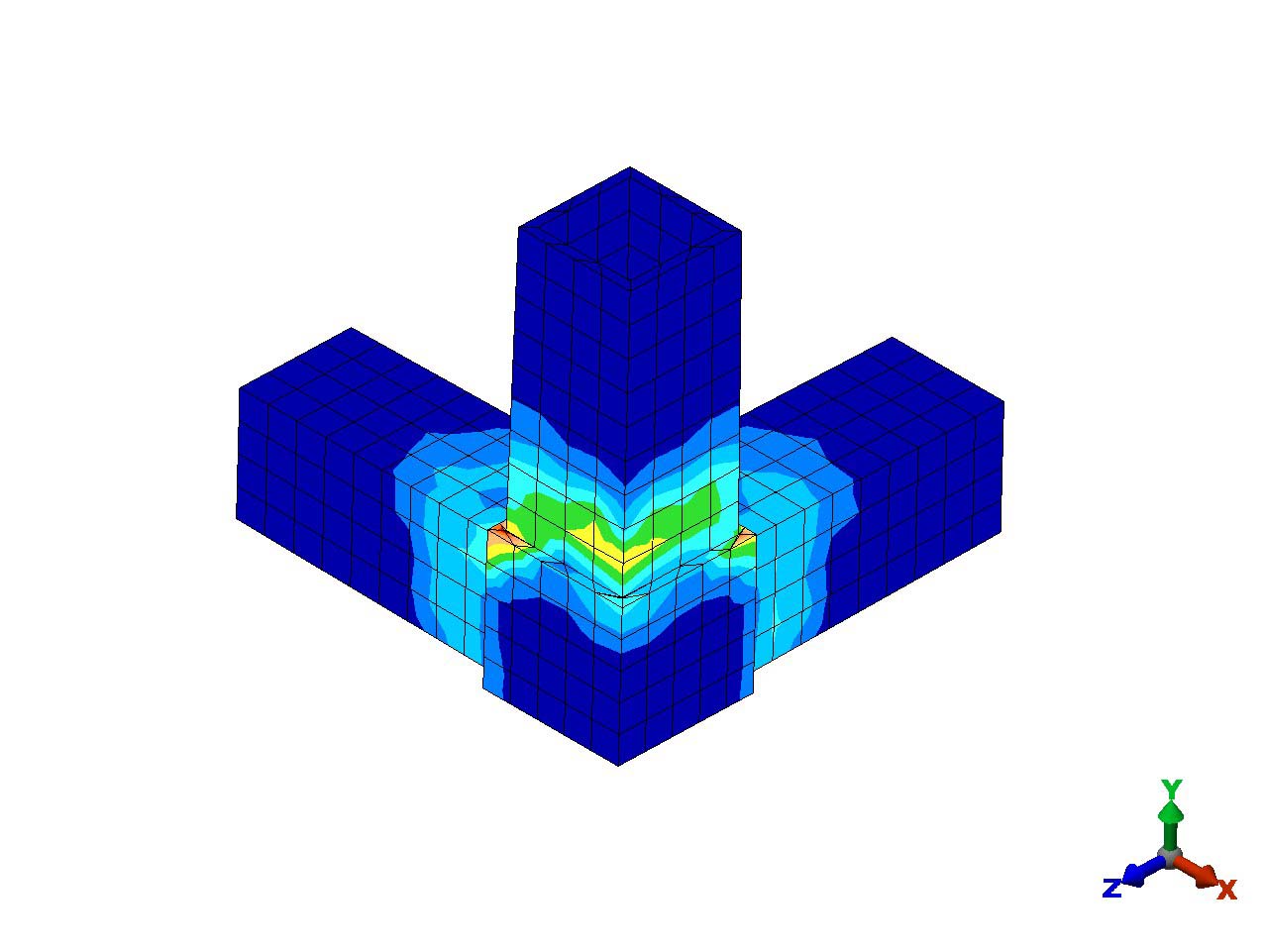

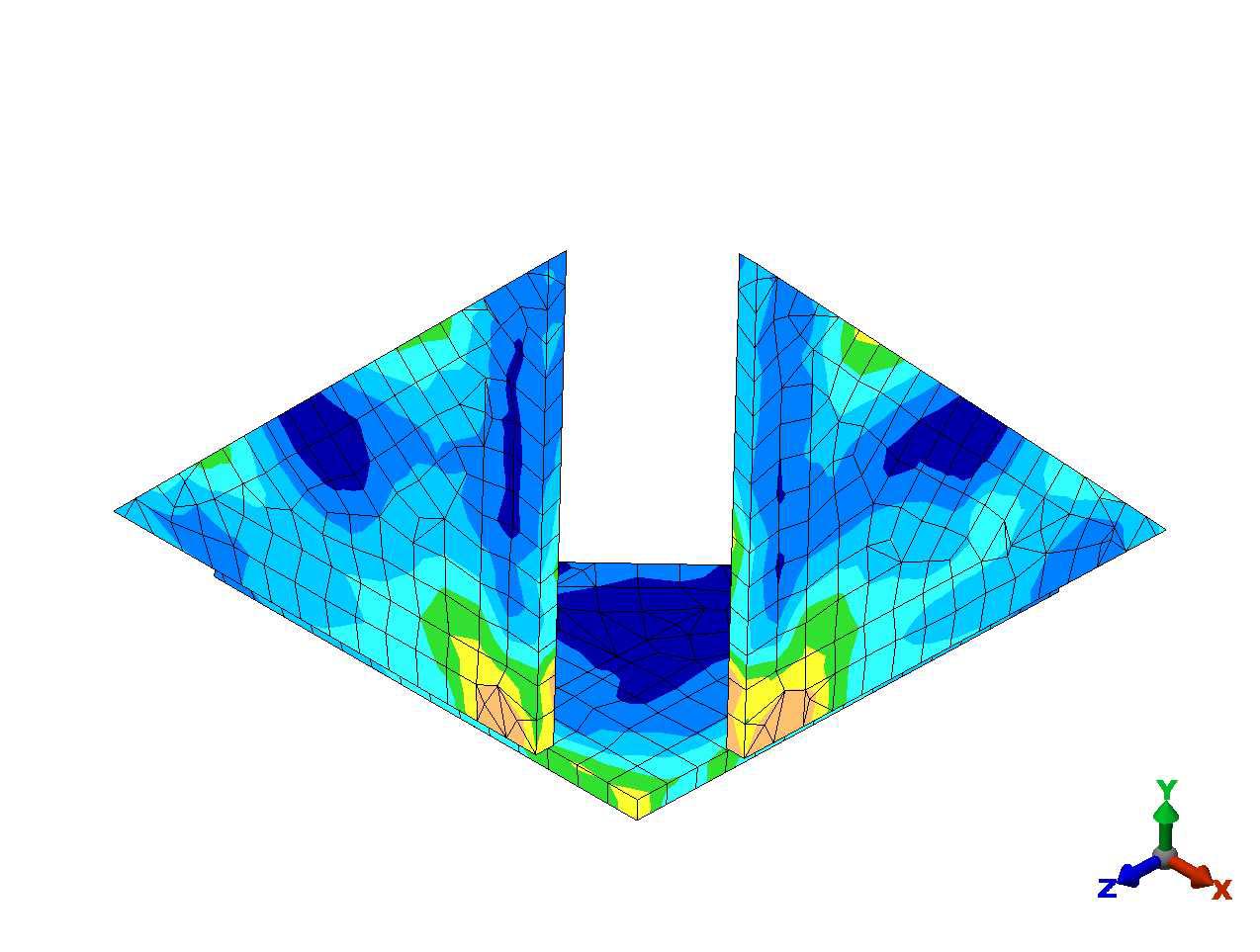

Algor via InCAD for creation of a FEA model. Four corners were modeled

individually for drop impact via vector steering to force the g loads to follow

an axis from the device Center of Gravity (CG) to a selected impact corner.

Fixed boundary conditions were placed on and around the fixed impact corner

under study. The FEA model consists of an assembly

of 74 parts plus 9 major components which were modeled as point microscopic beam

masses and located with virtual beam elements. This was nearly a 2 million

Degree of Freedom (DOF) model which is a fairly complex model. Color bars were removed to hide proprietary

data.

Portable Ultrasonic Cleaner Drop Impact Stress Results

Click on an Image to Display a Larger Image

|

|

|

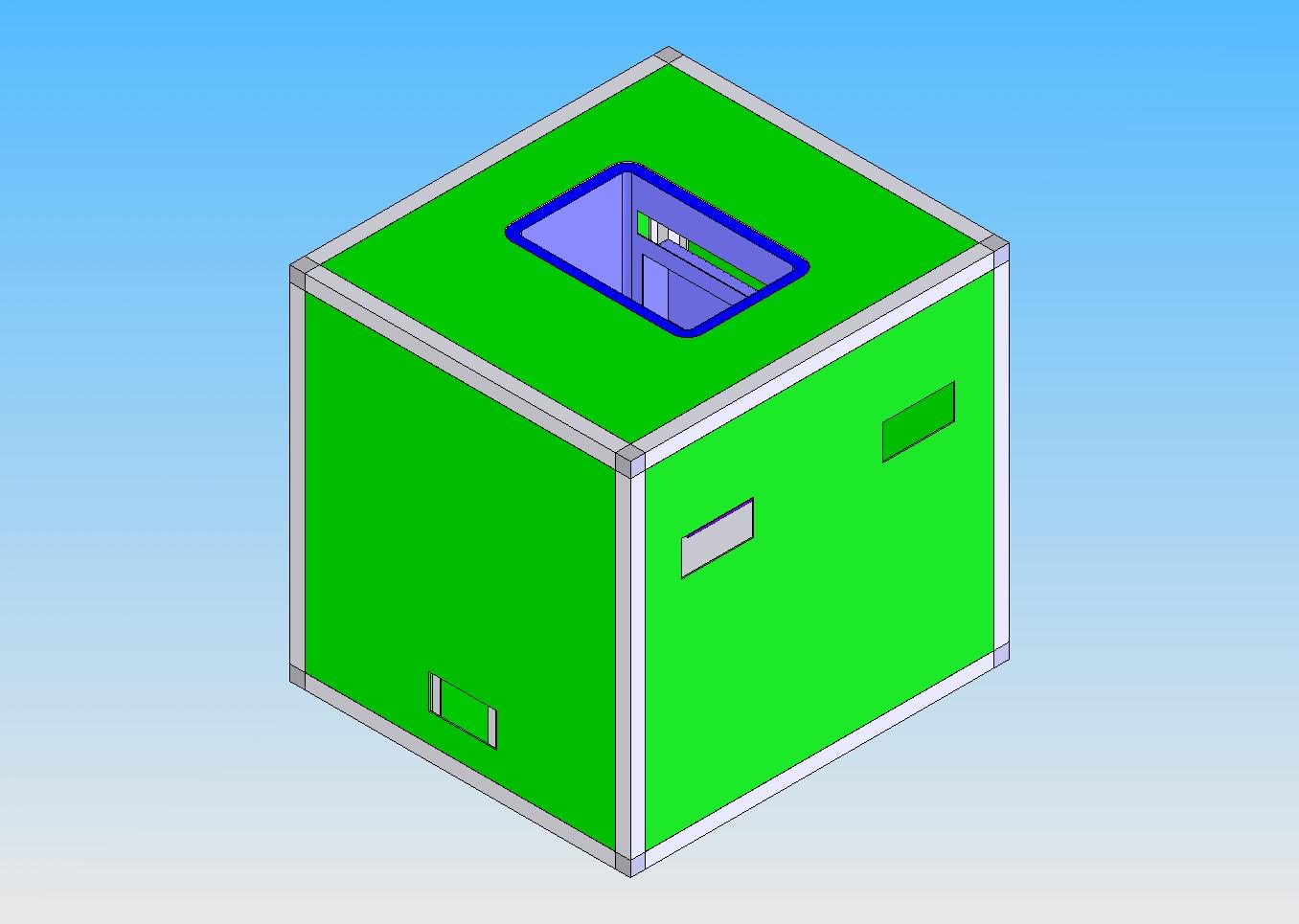

| SolidWorks Model Closed |

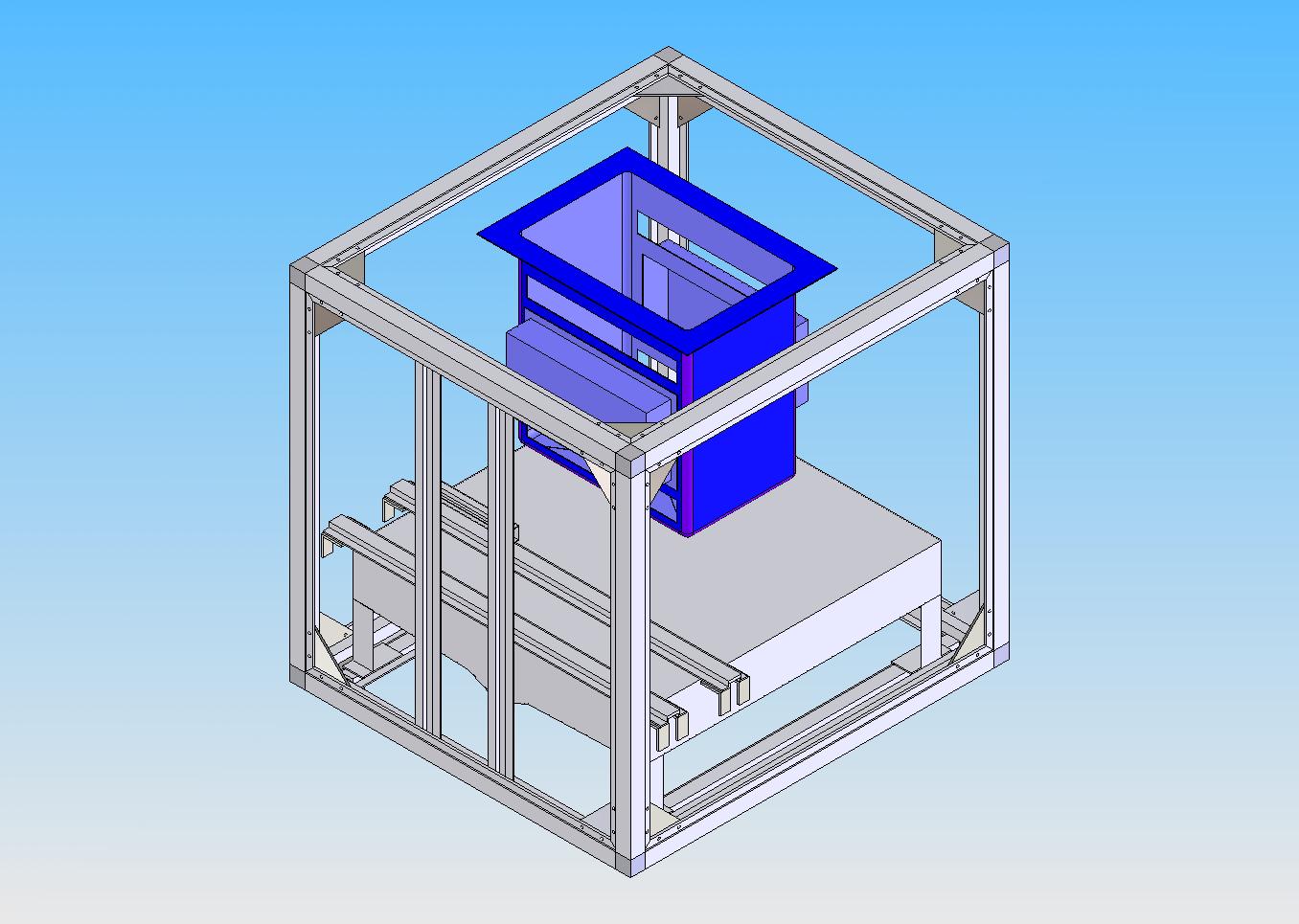

SolidWorks Model Open |

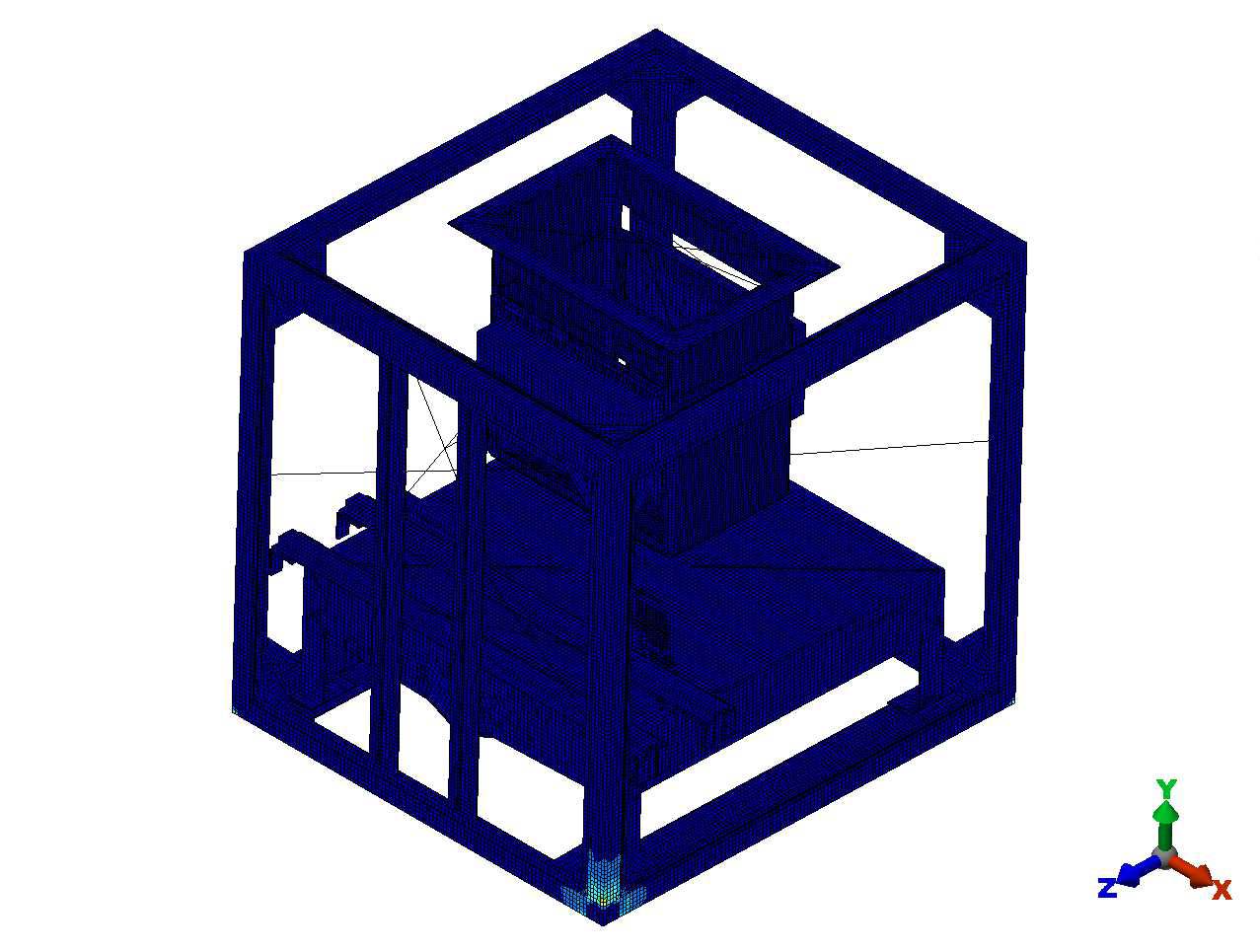

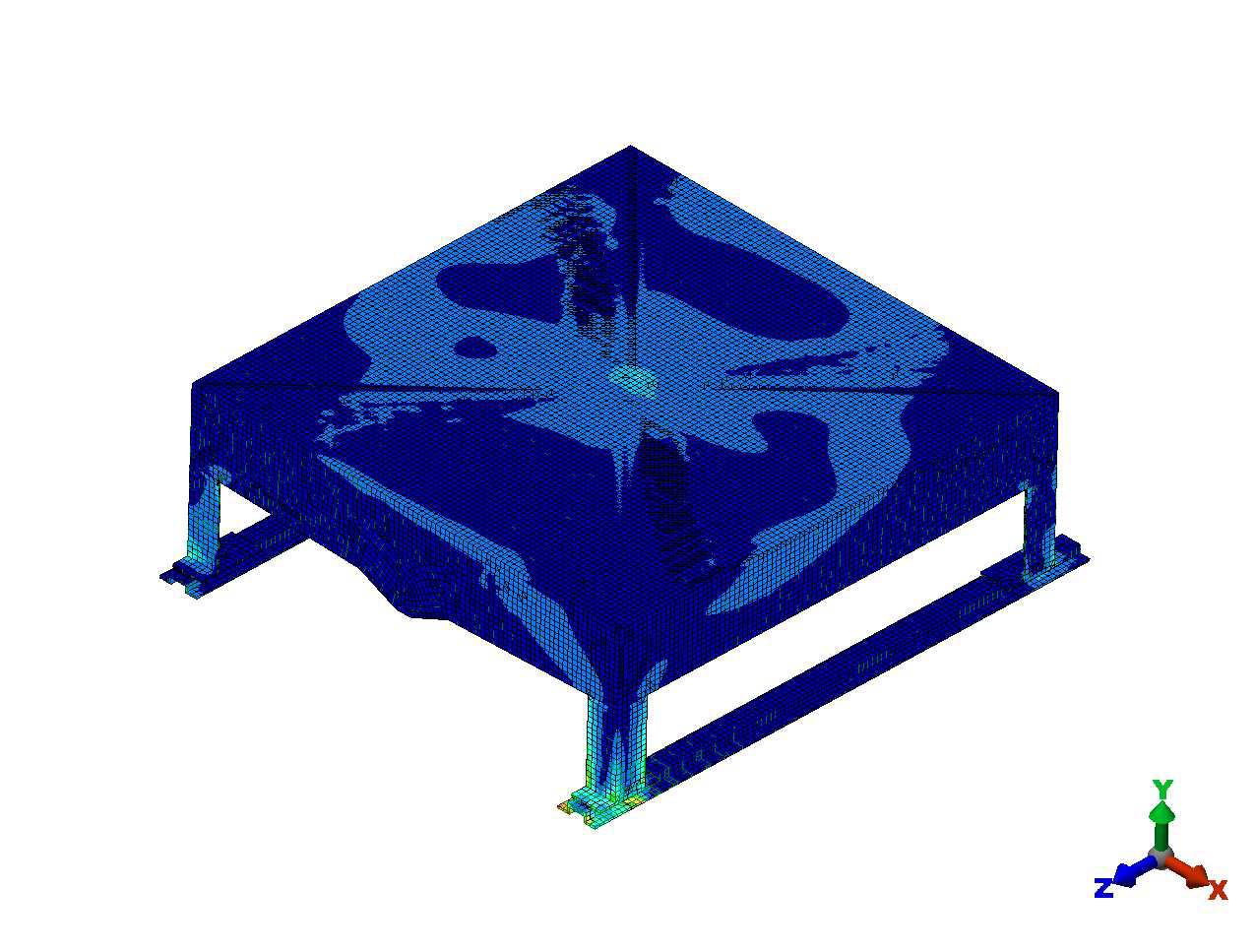

Algor FEA Impact Stress |

|

|

|

| Dump Tank |

Rinse Tank |

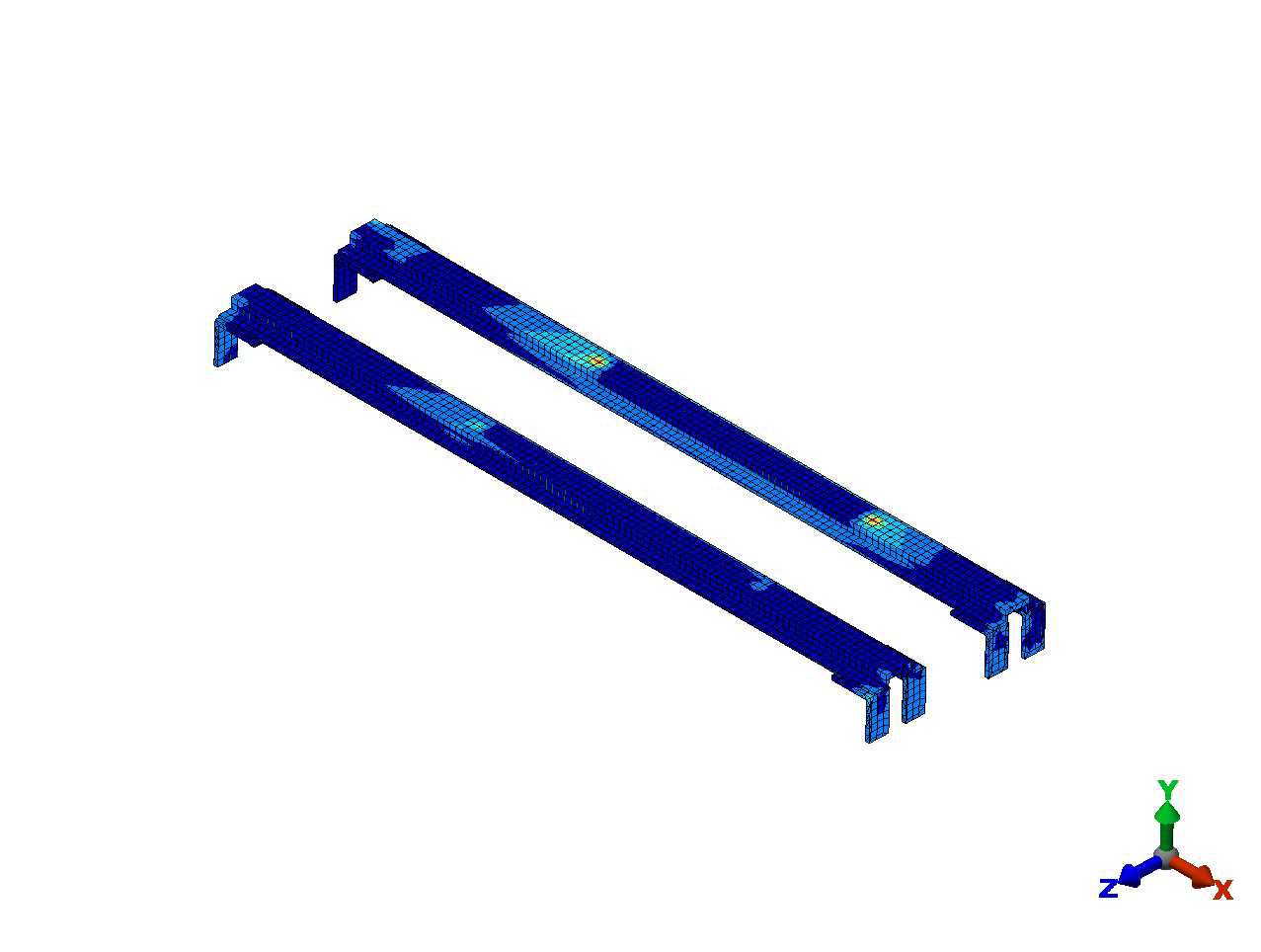

Leg Extrusions |

|

|

|

| Fixed Corner Casting |

Corner Gussets |

Vacuum Pump Mounts |

|